|

Risk Assessment of

Several Risks Combined

Case Study:

It is a rare project that has only a single

source of risk, so to determine the total impact of risk on

a project the elements must be combined. If we include all

possible sources of risk into the model, it will become

impossibly complicated, so we limit our attention to the

significant few, the 20 per cent that have 80 per cent of

the impact. The work breakdown structure is a key tool in

this integration of the risk. In practice, there are two

approaches:

- A top-down approach, in which key risk

factors are identified and assessed at a high level of work

breakdown, and managed out of the project

- A bottom-up approach. in which risks are

identified at a low level of work breakdown, and an

appropriate contingency made to allow for the risk

3.2.1 The Top-Down Approach

The top-down approach can provide managers

with checklist of potential risk factors based on previous

experience and can help them to determine each risk's

relative importance. Furthermore, by identifying the

controlling relationships at a high level it enables project

managers to find ways of eliminating the most severe risks

from their projects.

Figure 3.1 is the top-level network

for a simple project to build a warehouse where there are

four packages of work, see Table 3.1. Assuming end-to-start

dependencies only, the duration of the project is seven

months. It might be possible to fast track the project by

overlapping work packages. However let us assume that, that

is impossible on the path A-C-D: it is not possible to buy

the steel until the design is finished and because all the

steel will arrive at once, erection cannot begin until the

steel has arrived. It might be possible to start work on the

site before the design is finished, but there is no need

because the duration will be determined by the delivery of

the steel.

|

|

|

1 |

2 |

3 |

|

|

-2 |

Prepare site and foundation |

|

0 |

3 |

3 |

|

|

3 |

2 |

6 |

|

|

5 |

2 |

7 |

|

Design building and foundation |

|

|

|

|

|

Erect steelwork |

|

0 |

0 |

3 |

|

3 |

2 |

5 |

|

5 |

0 |

7 |

|

|

Procure steelwork |

|

|

3 |

0 |

5 |

Figure 3.1: Simple precedence network for

constructing a warehouse

Table 3.1: Project to erect a warehouse

|

No |

Name of Work Package |

Preceding Package |

Duration (Months) |

|

A |

Design building and foundation |

- |

3 |

|

B |

Prepare site and foundation |

A |

2 |

|

C |

Procures steelwork |

A |

2 |

|

D |

Erect steelwork |

B,C |

2 |

Now let us consider the risks. Let us assume

that the project will start at the beginning of September,

after the summer vacation. The risks are as follows:

1.

The design of the building may take more or

less than three months. From previous experience, we may be

able to say it will take two, three or four months with the

following probabilities:

-

2 months: 25 per cent

-

3 months: 50 per cent

-

4 months: 25 per cent

Hence it may be finished as early as the end

of October, or may stretch to the end of December.

2.

The site cannot he prepared if there is snow

on the ground. Snow occurs in four months of the year with

the following probabilities :

-

December: 25 per cent

-

January: 25 per cent

-

February: 50 per cent

-

March: 25 per cent

The duration of this work package is

dependent on when it starts.

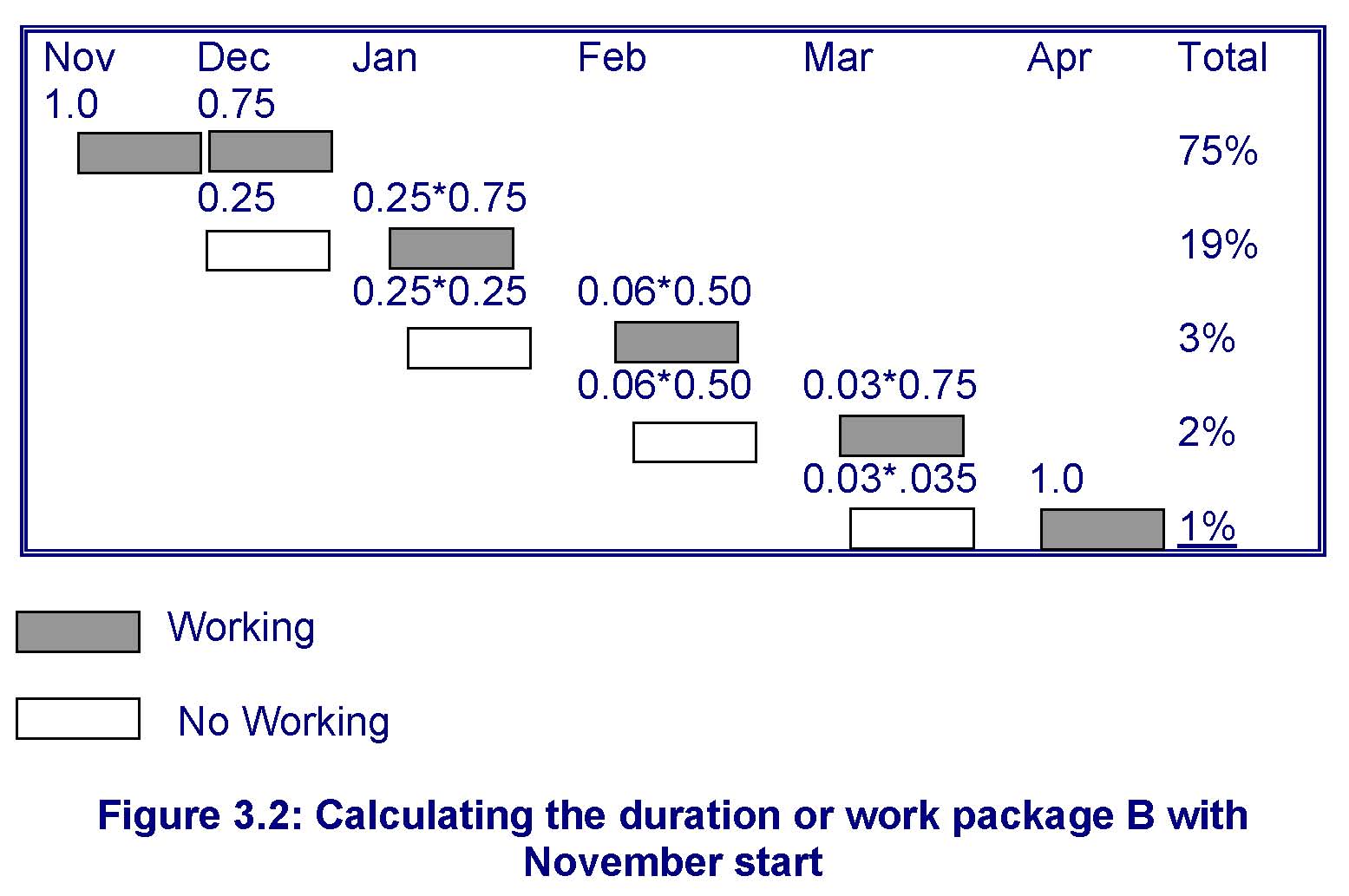

If it starts in October, it will take only two months; if it

starts in November, it will have the following range of

durations, see Figure 3.2.

-

2 months: 75 per cent

-

3 months: 19 per cent

-

4 months: 3 per cent

-

5 months: 2 per cent

-

6 months: 1 per cent

There will be similar tables if the work were

to start in December or January, but with the probabilities

weighted towards the longer durations. In some

circumstances, the preparation of the site will become

critical. Now it may be worthwhile trying to fast track the

design of the foundations. If the design could be completed

by the end of September, we could eliminate this risk

entirely. If it is finished by the end of October, there is

a 75 per cent chance of the work being finished on time. If

the start of this work is delayed to December, there is only

a 50 per cent chance. The choice will depend on the cost of

fast tracking the design of the foundations. There will be

additional financial charges if this work is completed

early, it is unlikely that the cost of the design will be

greater per se, but there is a risk of re-work as described

above in identifying risk. In the event, you may actually

make the decision on the day depending on how the design of

the steelwork is progressing, and on other factors below.

Figure 3.2: Calculating the duration or work

package B with November start

1.

There may be two possible suppliers of

steelwork: the more expensive one can deliver in one month

or two months with equal probability; and the cheaper in two

months or three months also with equal probability. The

delivery time therefore has the following distribution:

- 1 month: 25

per cent

-

2 months: 50 per cent

-

3 months: 25 per cent

On the face of it, this appears the same as

the design. However, the power of this top-down approach is

you can decide what to do on the day when you know how long

the design has taken and how you are progressing with the

foundations. To understand this we need to address the

fourth risk.

2.

This is that the steelwork cannot be erected

if there are strong winds, and these occur with the

following probability:

-

February: 25 per cent

-

March: 50 per cent

The duration of this work will also depend on

when it starts as with preparing the site. However, what we

can see is that if the design work finishes at the end of

October then it will be better to use the more expensive

supplier. There will then be a 50 percent chance that

erection can begin in December and finish in January without

any delay, or a 50 per cent chance that it will begin in

January, in which case it will finish in February with a 75

per cent chance. This is of course dependent on the

foundations being ready, and so if it looks as though the

steelwork design will be completed early then it will be

worthwhile fast tracking the foundations. On the other hand,

if the design takes four months, it would be better to use

the cheaper supplier and just plan to start erecting the

steelwork in April saving on extra cost of the foundations

and on having erection fitters standing idle.

This simple case shows that the top-down

approach allows you to analyze the interrelationships

between elements of risk, and management decisions based on

that analysis and the actual out-turn.

Following a top-down approach, you

are able to develop additional detail in some areas. In the

case above, for instance you could introduce a lower level

of work breakdown to find out how to fast track the design

of the foundations to reduce the risk. That requires the

design to be broken into smaller packages of work subject to

strict design parameters at the top level.

3.2.2 Influence Diagrams

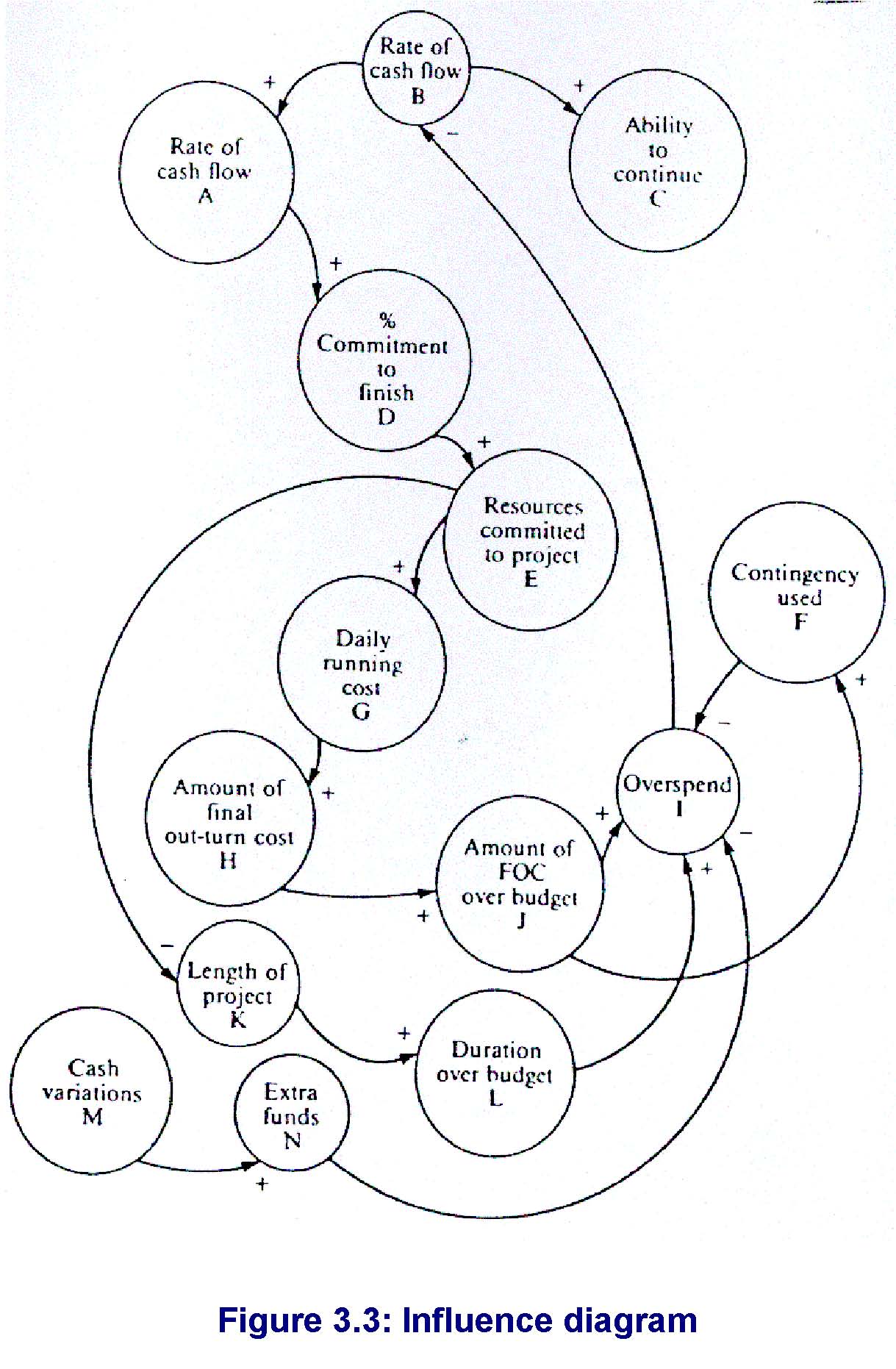

Influence diagrams are tools - derived from a

systems dynamics

approach -that can assist a top-down analysis.

They show how risks influence one another: some risks

reinforce others (+), and some reduce others (-).

Figure 3.3 is an example of an influence diagram. The

power of the technique is to identify loops of influence.

“Vicious cycles” have an even (or zero) number of

negative influences, and “stable cycles” an odd number. In

Figure 3.3 loop ADEKLIBA is vicious, and loop ADEGHJIBA is

stable. In “vicious cycle” an externally imposed influence

can be amplified indefinitely.

3.2.3 The Bottom-Up Approach

The bottom-up approach analyses risk at a low

level.

It can identify several critical paths, and

calculate a range of outcomes for cost and duration

to enable the project manager to allow appropriate

contingency. However, it is

essentially a negative approach to risk, as it assumes that

risk elements are beyond the control of managers. It does

nothing to help the manager to quantify or convey

information for developing an appropriate management

response to reducing or eliminating risk.

The approach develops a detailed project

model at a low level of breakdown. Variable durations

and / or costs are assigned to work element, as in the above

example. However, at a low level it is not possible to

calculate the various outcomes manually, as they were above.

Instead, we perform a Monte Carlo analysis. The

project model is analyzed many times: 100 to 10 000 is

typical depending on the size of the model. Each time a

random number is drawn for each parameter for which there is

a range of values, and a value selected accordingly. This

makes the simplifying assumption that the risk elements are

unrelated which may not be the case, see Figure 3.3. The

cost and duration are then calculated using those values and

a range of possible outcomes calculated for the project.

Effectively, the project is sampled however many times the

analysis is performed. The results of the Monte Carlo

analysis are presented as a probability distribution for

time cost or both. This may be a simple or cumulative

distribution. Figure 3.4 shows both distributions for the

duration of the warehouse project, assuming the logic given

in Table 3.1. For this simple case, the critical path may go

through either A-B-D or A-C-D, and the duration can be

anything from 6 to II months. The likelihood that either or

both of the routes will be the critical path is:

|

Critical path: |

A-B-D |

Both |

A-C-D |

|

Likelihood: |

52% |

24% |

24% |

Figure 3.3: Influence diagram

Figure

3.4: Simple and cumulative probability distributions for the

duration of the project to build a warehouse

|

Probability the duration will

equal outcome |

100%

80%

60%

40%

20% |

|

100%

80%

60%

40%

20%

|

Probability the duration is less

than outcome |

The range of all possible outcomes is:

Duration (months): 6 7

8 9 10 11

Probability: 5% 13%

31% 41% 8% 2%

Cumulative: 5% 18%

496% 90% 98% 100%

With a project this small, it is just

possible to calculate these numbers by hand. With anything

larger, the figures have to be determined using a Monte

Carlo analysis. From this we see that the median outcome is

eight months (half the time and the duration will be this or

less) and that 90 percent of the time the duration will be

less than nine months. The most likely duration (the mode)

is nine months. If nine month duration is acceptable, we may

accept these figures. If not, we would need to shorten the

project. The critical path figures show that the most useful

effort may be put into shortening A-B-D and that may suggest

fast tracking the design of the foundations. However, from

this we do not see the effect of the two suppliers. That can

only be analyzed by the top- down approach.

|

Risk Assessment and

Risk Management(3)

Risk Assessment and

Risk Management(3)